© 2024 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ TIJ Inkjet - Print Personalisation and Numbering

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The CFS-606 covers all requirements in terms of fully

automatic numbering and coding on continuous forms

like business forms, NCR form sets, event tickets, gift

vouchers, certificates etc. but also on high-security

documents like bank drafts, cheques, visa and other

ID related documents.

Due to its modular construction, the machine can be

extended by retrofitting with further numbering and

hologram heads as well as label dispensers for

tandem units, also at any later date.

Numbering and imprinting heads of the series SU

In combination with the RADUS numbering heads of

the SU series, numberings in Gothic, CMC 7, E 13B and OCR as well as barcode, signatures and logos can

be printed. A printing head change is possible within minutes.

● SU1

Whenever simple numbering is required, the SU1 numbering head, proven thousands of times in use, can

demonstrate its performance. With the extremely low printing costs, it is unrivalled in its field of application.

Oil-based stamping inks are used for printing on absorbent materials made from paper. Used in combination

with steel rotary numbering machines, the controllable pressure setting of the SU printing heads provides

easy crash numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the Radus SU2 numbering head is an impressive direct

development of the tried-and-tested SU1. This allows the imprinting of high-quality Gothic and OCR

numbering, as well as barcode, in all types of document. Optionally, the numbering head SU2 is also

available as Computerized CRN variant. (Computer Random Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding using special carbon ribbons. The ink on

a carrier film is transferred cold, directly to the paper, using pressure from the numbering unit. The

numbering head processes carbon ribbons for OCR and MICR numbering, as well as black ribbons with

additional security features, such as UV fluorescence yellow / green and indelible red ink penetration - bleed

through. Replacing the rotary numbering machine with magnetic print blocks enables the imprinting of

signatures and logos.

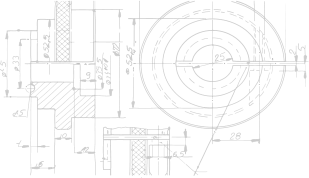

Tractor system

The tractor system processes fanfold continuous forms up to a width of 19" including sprocket-holes and

operates in the base from pack to pack. Depending on the application, the system can be operated via

contactless loop switches directly with un- and rewinding units. The processor-controlled system with its two

well dimensioned tractors provides a regular paper transport and guidance of the web. The adjustable

processing speed of the web allows an individual adaptation to the paper quality. Short distances between

tractor system and printing station ensure less paper waste in the machine setup.

Operating process

By the tractors the web is moved to the printing station. Here, one or two SU heads can be used. The form is

stopped under the printing heads at the required position; imprinting then takes place. The operator selects

whether one or both heads are used for imprinting at the position. After imprinting, the form is moved to the

next position. In this way, each form can be imprinted or numbered in 25 freely-selectable positions, e.g. for

tickets, tax labels or cheques arranged one above the other. An optional OMR recognition also allows

dependency controlled imprinting over print marks.

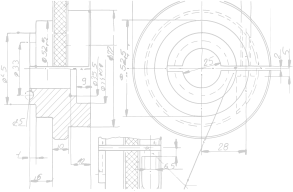

RADUS CFS-606 / 601

Numbering and Coding System

SPECIFICATIONS

Functions / Features

• Basic system CFS-606 with transport for continuous forms

• Basic system CFS-601 without transport as extension station

for all RADUS CFS modules as well as for direct coupling with

BOWE paper cutters

• Basic system from 1 x numbering head series SU

• Rotary numbering maschines with standard and customized

• Direct coupling with further labeling and hologram stations

Basic Model CFS-606 / CFS-601

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ Touch display

Transport System (pinfeed)

Form width

3”-19” incl. sprocket holes cent. adjustment

Form length

1/6” - 33” - 1/6”, 1/8”, and 1/10” feed division

Resolution

1/120”

Paper weight

40- 200g/m² - form sets up to 400g/m²

Transport System (pinless)

Form width

50mm - 500mm

Form length

10mm - 800mm

Resulution

0,1mm

Paper weight

max. approx. 400g/m²

Print mark

fork light barrier / print mark reader

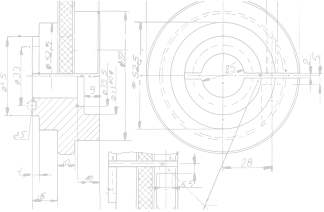

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering

machines of steel / opt. pre-inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and

Logos

SU4

Print head for carbon ribbons, single and multi

strike, optional with MICR, UV fluorescence

yellow / green and indelible red ink penetration -

bleed through, other ribbons on request

Print carrier

Rotary numbering machines of steel or part

carrierFonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text

and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 1550mm x depth 1000mm x height 1500mm

Weight

approx. 150kg (depending on configuration)

Performance

up to 16.500 numberings/h per SU-head

up to 15.000 hologram applications/h per HP3-head

up to 20.000 labelings/h per LD4-head

- All Products Overview

- Hologram Polycarbonate

- Hologram Sheet-Fed

- Hologram Continious Forms

- UV-DOD Inkjet Personalisation

- TIJ Inkjet Print Personalisation

- RFID Personalization

- Numbering Sheet-Fed

- Numbering Continuous Forms

- Numbering Manual Handling

- Numbering Heads

- Numbering Ribbons

- Scratch Application

© 2024 Arnold Herzig GmbH • Germany - All rights reserved

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Bleed Through

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application Hot Stamping Polycarbonate

■ Hologram Applicator for Sheet-Fed - Paper

■ Hologram Applicator for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The CFS-606 covers all requirements in terms of fully automatic

numbering and coding on continuous forms like business forms, NCR

form sets, event tickets, gift vouchers, certificates etc. but also on high-

security documents like bank drafts, cheques, visa and other ID related

documents.

Due to its modular construction, the machine can be extended by

retrofitting with further numbering and hologram heads as well as label

dispensers for tandem units, also at any later date.

Numbering and imprinting heads of the series SU

In combination with the RADUS numbering heads of the SU series,

numberings in Gothic, CMC 7, E 13B and OCR as well as barcode,

signatures and logos can be printed. A printing head change is possible

within minutes.

● SU1

Whenever simple numbering is required, the SU1 numbering head,

proven thousands of times in use, can demonstrate its performance.

With the extremely low printing costs, it is unrivalled in its field of

application. Oil-based stamping inks are used for printing on absorbent

materials made from paper. Used in combination with steel rotary

numbering machines, the controllable pressure setting of the SU printing

heads provides easy crash numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the Radus SU2 numbering

head is an impressive direct development of the tried-and-tested SU1.

This allows the imprinting of high-quality Gothic and OCR numbering, as

well as barcode, in all types of document. Optionally, the numbering head

SU2 is also available as Computerized CRN variant. (Computer Random

Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding

using special carbon ribbons. The ink on a carrier film is transferred cold,

directly to the paper, using pressure from the numbering unit. The

numbering head processes carbon ribbons for OCR and MICR

numbering, as well as black ribbons with additional security features,

such as UV fluorescence yellow / green and indelible red ink penetration

- bleed through. Replacing the rotary numbering machine with magnetic

print blocks enables the imprinting of signatures and logos.

Tractor system

The tractor system processes fanfold continuous forms up to a width of

19" including sprocket-holes and operates in the base from pack to pack.

Depending on the application, the system can be operated via

contactless loop switches directly with un- and rewinding units. The

processor-controlled system with its two well dimensioned tractors

provides a regular paper transport and guidance of the web. The

adjustable processing speed of the web allows an individual adaptation

to the paper quality. Short distances between tractor system and printing

station ensure less paper waste in the machine setup.

Operating process

By the tractors the web is moved to the printing station. Here, one or two

SU heads can be used. The form is stopped under the printing heads at

the required position; imprinting then takes place. The operator selects

whether one or both heads are used for imprinting at the position. After

imprinting, the form is moved to the next position. In this way, each form

can be imprinted or numbered in 25 freely-selectable positions, e.g. for

tickets, tax labels or cheques arranged one above the other. An optional

OMR recognition also allows dependency controlled imprinting over print

marks.

RADUS CFS-606 / 601

Numbering and Coding System

SPECIFICATIONS

Functions / Features

• Basic system CFS-606 with transport for continuous forms

• Basic system CFS-601 without transport as extension station

for all RADUS CFS modules as well as for direct coupling with

BOWE paper cutters

• Basic system from 1 x numbering head series SU

• Rotary numbering maschines with standard and customized

• Direct coupling with further labeling and hologram stations

Basic Model CFS-606 / CFS-601

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ Touch display

Transport System (pinfeed)

Form width

3”-19” incl. sprocket holes cent. adjustment

Form length

1/6” - 33” - 1/6”, 1/8”, and 1/10” feed division

Resolution

1/120”

Paper weight

40- 200g/m² - form sets up to 400g/m²

Transport System (pinless)

Form width

50mm - 500mm

Form length

10mm - 800mm

Resulution

0,1mm

Paper weight

max. approx. 400g/m²

Print mark

fork light barrier / print mark reader

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering

machines of steel / opt. pre-inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and

Logos

SU4

Print head for carbon ribbons, single and multi

strike, optional with MICR, UV fluorescence

yellow / green and indelible red ink penetration -

bleed through, other ribbons on request

Print carrier

Rotary numbering machines of steel or part

carrierFonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text

and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 1550mm x depth 1000mm x height 1500mm

Weight

approx. 150kg (depending on configuration)

Performance

up to 16.500 numberings/h per SU-head

up to 15.000 hologram applications/h per HP3-head

up to 20.000 labelings/h per LD4-head

© 2024 Arnold Herzig GmbH • Germany - All rights reserved

Smart and Innovative Solutions for the Security Printing Industry

Smart and Innovative Solutions - since 1964

Arnold Herzig GmbH

The CFS-606 covers all requirements in terms of fully automatic numbering and coding on

continuous forms like business forms, NCR form sets, event tickets, gift vouchers, certificates

etc. but also on high-security documents like bank drafts, cheques, visa and other ID related

documents.

Due to its modular construction, the machine can be extended by retrofitting with further

numbering and hologram heads as well as label dispensers for tandem units, also at any later

date.

Numbering and imprinting heads of the series SU

In combination with the RADUS

numbering heads of the SU series,

numberings in Gothic, CMC 7, E 13B

and OCR as well as barcode,

signatures and logos can be printed.

A printing head change is possible

within minutes.

● SU1

Whenever simple numbering is

required, the SU1 numbering head,

proven thousands of times in use, can

demonstrate its performance. With the

extremely low printing costs, it is

unrivalled in its field of application. Oil-based stamping inks are used for printing on

absorbent materials made from paper. Used in combination with steel rotary numbering

machines, the controllable pressure setting of the SU printing heads provides easy crash

numbering of NCR form sets.

● SU2 / SU2-CRN

With the sophisticated letterpress inking unit, the Radus SU2 numbering head is an

impressive direct development of the tried-and-tested SU1. This allows the imprinting of high-

quality Gothic and OCR numbering, as well as barcode, in all types of document. Optionally,

the numbering head SU2 is also available as Computerized CRN variant. (Computer Random

Numbering)

● SU4

The SU4 numbering head was developed for numbering and coding using special carbon

ribbons. The ink on a carrier film is transferred cold, directly to the paper, using pressure from

the numbering unit. The numbering head processes carbon ribbons for OCR and MICR

numbering, as well as black ribbons with additional security features, such as UV

fluorescence yellow / green and indelible red ink penetration - bleed through. Replacing the

rotary numbering machine with magnetic print blocks enables the imprinting of signatures and

logos.

Tractor system

The tractor system processes fanfold continuous forms up to a width of 19" including

sprocket-holes and operates in the base from pack to pack. Depending on the application,

the system can be operated via contactless loop switches directly with un- and rewinding

units. The processor-controlled system with its two well dimensioned tractors provides a

regular paper transport and guidance of the web. The adjustable processing speed of the

web allows an individual adaptation to the paper quality. Short distances between tractor

system and printing station ensure less paper waste in the machine setup.

Operating process

By the tractors the web is moved to the printing station. Here, one or two SU heads can be

used. The form is stopped under the printing heads at the required position; imprinting then

takes place. The operator selects whether one or both heads are used for imprinting at the

position. After imprinting, the form is moved to the next position. In this way, each form can be

imprinted or numbered in 25 freely-selectable positions, e.g. for tickets, tax labels or cheques

arranged one above the other. An optional OMR recognition also allows dependency

controlled imprinting over print marks.

RADUS CFS-606 / 601

Numbering and Coding System

SPECIFICATIONS

Functions / Features

• Basic system CFS-606 with transport for continuous forms

• Basic system CFS-601 without transport as extension station

for all RADUS CFS modules as well as for direct coupling with

BOWE paper cutters

• Basic system from 1 x numbering head series SU

• Rotary numbering maschines with standard and customized

• Direct coupling with further labeling and hologram stations

Basic Model CFS-606 / CFS-601

Controlling

Microprocessor

Operation

Fully automatic / intermittent

Controll desk

7“ Touch display

Transport System (pinfeed)

Form width

3”-19” incl. sprocket holes cent. adjustment

Form length

1/6” - 33” - 1/6”, 1/8”, and 1/10” feed division

Resolution

1/120”

Paper weight

40- 200g/m² - form sets up to 400g/m²

Transport System (pinless)

Form width

50mm - 500mm

Form length

10mm - 800mm

Resulution

0,1mm

Paper weight

max. approx. 400g/m²

Print mark

fork light barrier / print mark reader

Numbering and Imprinting Heads SU-Series

SU1

Print head for stamp inks, oil-based

Print carrier

Rotaty numbering machines of steel

Fonts

e.g. gothic as well as custom engravings

SU2

Print head for letterpress inks, security printing inks

Print carrier

Rotary barcode / numbering

machines of steel / opt. pre-inker

Fonts

e.g. gothic, OCR-A, OCR-B, barcode, text and

Logos

SU4

Print head for carbon ribbons, single and multi

strike, optional with MICR, UV fluorescence

yellow / green and indelible red ink penetration -

bleed through, other ribbons on request

Print carrier

Rotary numbering machines of steel or part

carrierFonts

e.g. gothic, OCR-A, OCR-B, E13 B, CMC7, text

and logos

Connections

Electrical con.

single phase 220-240V, 50/60Hz, 110V optional

Dimensions

Length 1550mm x depth 1000mm x height 1500mm

Weight

approx. 150kg (depending on configuration)

Performance

up to 16.500 numberings/h per SU-head

up to 15.000 hologram applications/h per HP3-head

up to 20.000 labelings/h per LD4-head

■ Product Overview

■ Security Document with Numbering - UV Fluo. / Red Penetration

■ Security Document with Hologram Application

■ Embedded DOVID / Hologram Application with Hot Stamping on Polycarbonate

■ Hologram Applicator Machine for Sheet-Fed - Paper

■ Hologram Applicator Machine for Continuous Forms

■ RFID Technology - Chip Encoding and Print Personalization

■ RFID Transponder - Smart Cards and Smart Tickets ISO CR80 / ID-1

■ RFID Transponder - Smart Tickets and Smart Labels from Roll

■ UV-DOD Inkjet - Print Personalization and Serialization Machine